Abstract

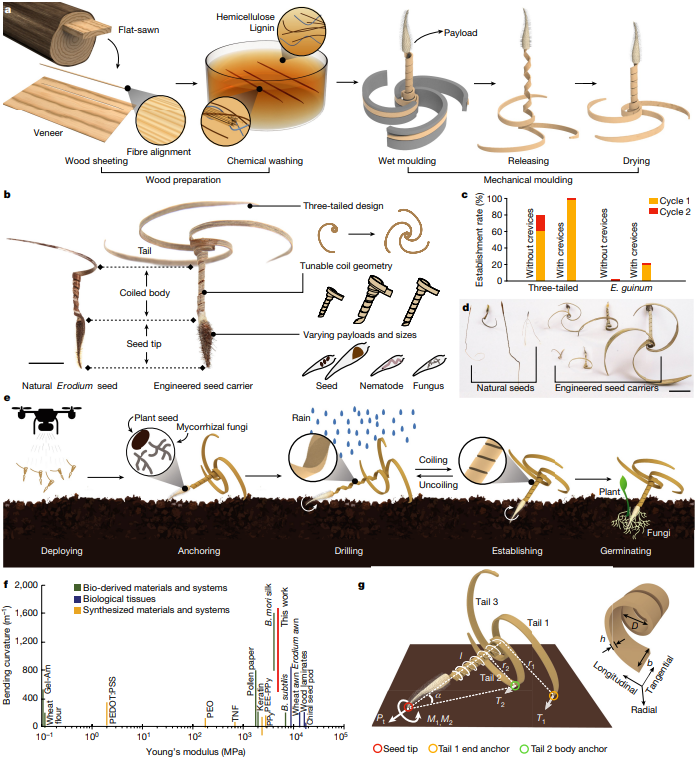

Aerial seeding can quickly cover large and physically inaccessible areas1 to improve soil quality and scavenge residual nitrogen in agriculture2, and for postfire reforestation3,4,5 and wildland restoration6,7. However, it suffers from low germination rates, due to the direct exposure of unburied seeds to harsh sunlight, wind and granivorous birds, as well as undesirable air humidity and temperature1,8,9. Here, inspired by Erodium seeds10,11,12,13,14, we design and fabricate self-drilling seed carriers, turning wood veneer into highly stiff (about 4.9 GPa when dry, and about 1.3 GPa when wet) and hygromorphic bending or coiling actuators with an extremely large bending curvature (1,854m-1), 45 times larger than the values in the literature15,16,17,18. Our three-tailed carrier has an 80% drilling success rate on flat land after two triggering cycles, due to the beneficial resting angle (25°–30°) of its tail anchoring, whereas the natural Erodium seed’s success rate is 0%. Our carriers can carry payloads of various sizes and contents including biofertilizers and plant seeds as large as those of whitebark pine, which are about 11 mm in length and about 72 mg. We compare data from experiments and numerical simulation to elucidate the curvature transformation and actuation mechanisms to guide the design and optimization of the seed carriers. Our system will improve the effectiveness of aerial seeding to relieve agricultural and environmental stresses, and has potential applications in energy harvesting, soft robotics and sustainable buildings.

Fig. 1 | Bioinspired design of the autonomous self-drilling seed carrier. a, The processing steps to create wood-based hygromorphic actuators with a large initial curvature. b, The natural E. guinum seed that serves as the design inspiration, and our design concepts of the autonomous self-drilling seeding carrier with customized awn and tailored payloads. Scale bar, 10?mm. c, Our engineered three-tailed seed carrier has 80% higher establishment rates than the Erodium seed in the controlled self-drilling test (see Methods). n=10 seeds of each type. d, Engineered and natural seed carriers of various sizes and geometries (Supplementary Table 1). Scale bar, 20 mm. e, A possible application showing a three-tailed carrier delivering vegetable seeds alongside mycorrhizal fungi as symbiotic biofertilizers. f, Comparison of our actuator in elastic modulus and bending curvature with typical biological and engineered actuators and materials that exhibit hydration-induced reversible deformation behaviours (see Supplementary Table 2 for additional references and values). Gel-Am, gelatin–amyloid; PEDOT:PSS, poly(3,4-ethylenedioxythiophene):poly (styrene sulfonate); PEO, polyethylene oxide; TNF, titanium oxide nano-capillary forest; PEE-PPy, pentaerythritol ethoxylate-polypyrol; PPy, polypyrol; B. mori silk, Bombyx mori silk. B. subtilis, Bacillus subtilis. g, Three-tailed design considerations. Successful drilling relies on the effective vertical thrust force (Pt) and torque (M1, M2) that are determined by the moisture-driven mechanics coupled with the wood and the coil’s dimensional factors, including the thickness (h), width (b), diameter (D) and the coil’s active length (l) and tail configurations.

This work was contributed by Danli Luo1 , Aditi Maheshwari2 , Andreea Danielescu2 , Jiaji Li3 , Yue Yang3 , Ye Tao4 , Lingyun Sun3 , Dinesh K. Patel1 , Guanyun Wang1,3*, Shu Yang5*, Teng Zhang6,7*& Lining Yao1*

1

Morphing Matter Lab, Human-Computer Interaction Institute, Carnegie Mellon University, Pittsburgh, PA, USA.

2

Accenture Labs, San Francisco, CA, USA.

3

College of Computer Science and

Technology, Zhejiang University, Hangzhou, China.

4

School of Art and Archeology, Zhejiang University City College, Hangzhou, China.

5

Materials Science and Engineering, University of

Pennsylvania, Philadelphia, PA, USA.

6

Department of Mechanical and Aerospace Engineering, Syracuse University, Syracuse, NY, USA.

7

BioInspired Syracuse, Syracuse University, Syracuse, NY,

USA.

and published on Nature volume 614, pages 463–470 (2023) https://www.nature.com/articles/s41586-022-05656-3

Copyright © 2024 International Society of Bionic Engineering All Rights Reserved

吉ICP备11002416号-1