Author:Qi Zhang, Ke Wang, Xianchun Chen, Xiaohong Tang, Qian Zhao, Qiang Fu

Highlights

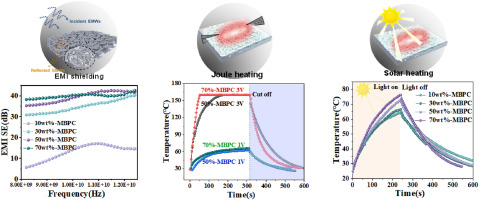

A biomass multifunctional composite (MBPC) based on metallized bamboo fiber was prepared.

The MBPC exhibit improved thermal stability and mechanical properties due to electroless plating treatment.

The MBPC possesses excellent EMI SE, joule heating, and solar heating properties.

The energy and environmental problems brought by petrochemical products promote the development of green and sustainable materials. Natural fiber reinforced plant-derived polylactic acid (PLA) is an attractive sustainable strategy. However, the lack of functionality largely limits its wider application. In this study, the most promising bamboo fiber (BF) whose versatility was realized by electroless plating (ELP) was selected as the reinforcing phase. By filling metallized BF(MBF) into PLA and then treating it by hot pressing, a low-cost, multifunctional MBF/PLA biomass composite(MBPC) was prepared. Results show that the ELP treatment of BF can not only significantly improve the thermal stability and mechanical properties of the composites but also endow it with excellent electromagnetic shielding, electro-thermal and photo-thermal conversion capabilities. Thereinto, the 70 wt%-MBPC has an electrical conductivity of 20.86 S/cm and an SE value of 45 dB in the X-band. The greater concern is the amazing electrothermal conversion performance, which can be heated rapidly at low voltage. Under the voltage of 3V, the temperature reaches 160 °C in about 50s. Besides, MBPC also possesses solar-driven heating, which can be rapidly heated to 75 °C under irradiation within 240s. This green and low-cost biomass multifunctional composite is expected to be used for electromagnetic shielding, energy conversion, and smart furniture, etc.

Graphical abstract

Introduction

In the past decades, petroleum-based products have played an indispensable role in the development of human society, bringing great convenience to human production and life. However, with the continuous growth of global economy, energy and environmental problems associated with petrochemicals have emerged, sparking widespread global interest in green, bio-based, and biodegradable materials. Currently, the global commercial production of bioplastics is growing rapidly, accounting for about 25–30% of the total plastics market in 2020. Among them, the plant origin polylactic acid(PLA) is considered the most promising biodegradable material, due to its excellent mechanical properties, biocompatibility, and complete degradability. Although PLA has the advantages mentioned above, its inherent brittleness, single function, high cost, and poor thermal stability also limit its application scope to some extent .

The introduction of natural fiber reinforcement is an effective strategy to enhance the performance of PLA, which can not only solve the application defects, and significantly reduce the cost of production, but also increase the added value of natural fibers. The applications of wood fiber , bamboo fiber (BF) , hemp fiber, and sugarcane fiber in PLA modification have been reported before. Thereinto, BF has the advantages of low cost and abundant natural sources, whose global annual output can reach 3 × 1010 kg, coupled with the merit of a short growth cycle and high specific strength, thus being called “the most promising plant in the 21st century” .

Most of the existing studies focused on improving the interfacial compatibility of BF/PLA (BPC) to further improve the mechanical properties of the composite. Alkali treatment , silane coupling treatment , and heat treatment are the most traditional modification methods. Scholars have also proposed various new methods, such as in situ polymerization of epoxidized soybean oil , grafted PLA , and deposition of mussel-inspired dopamine , which have improved the mechanical properties to varying degrees.

On this basis, the lack of functionality is a common defect of BF and PLA, which greatly limits its wider application, hence it is urgent to expand the versatility of BPC. Particularly, under the background of energy shortage and the rapid development of information technology, exploiting BPC for high-end applications such as energy conversion and electromagnetic shielding is urgently needed. Filling the third phase functional particles and covering the functional coating on the BF surface are two main strategies to endow BPC with functionality. Zhang et al. prepared BPC with antistatic properties by coating BF with a layer of polypyrrole. Niu et al., coated phosphorus-silica hybrid aerogel on the BF surface and then added ammonium polyphosphate to co-fill into PLA to prepare flame retardant composites. In general, there are fewer studies on the functionalization of BPC.

Compared with the preparation method of adding third-phase conductive particles, the surface metallization of BF has lower cost and weight, providing another idea for the preparation of high-efficiency, low-cost, and degradable biomass function materials. In our previous research, it was found the deposition of Ni–Fe–P alloy on the BF surface by electroless plating (ELP) can not only effectively improve the thermal stability, but more importantly, it can also impart BF with new electrical, thermal, and magnetic conductivity . Therefore the ELP method is proposed for the metallization of BF. In similar studies, scholars plated Ag on the BF surface and then dispersed Ag–BF in PLA to prepare biomass composites. Unfortunately, the report only focused on the antibacterial properties, and lacked the concern about other functions. Zhang et al. prepared bamboo plastic electromagnetic shielding material by filling Ni-plated BF into HDPE, and the results showed that the EMI SE reached 82 dB at 0.1–2 GHz, revealing the application potential of ELP in improving the function of biomass composite. On the basis, the metallized BF was developed into PLA to prepare all biomass composite in this study, and the multifunctionality which includes EMI shileding, electro-thermal, and photo-thermal conversion properties of the materials is investigated comprehensively.

Herein, BF with electroless Ni–Fe–P layer was dispersed into PLA to prepare a multifunctional bamboo plastic composite (MBPC). It should be noticed that this is a very scalable preparation method, and besides PLA, other plastic matrices such as PE and PP can be used to prepare multifunctional bamboo-plastic composites. The effects of ELP on the functionality, mechanical strength, and melting crystallization behavior of MBPC were systematically studied by changing the content of metallized BF(MBF) and metal deposit. The results revealed the alloy coating can not only significantly improve the thermal stability and mechanical strength, but also endows the composites with excellent electrical conductivity, shielding properties, and outstanding electro-thermal and photo-thermal conversion properties, showing the application prospect of MBPC in the fields of electromagnetic shielding and energy conversion.

Copyright © 2024 International Society of Bionic Engineering All Rights Reserved

吉ICP备11002416号-1