Research Progress

CNT/MOF nanocomposites enhance the performance of humidity sensors

Post: 2017-11-08 16:13 View:2448

| Metal-organic frameworks (MOFs) are well-ordered, lattice-like crystals. The nodes of the lattices are metals – such as copper, zinc, nickel or cobalt – which are connected by organic molecules. Their size-controllable nanopores, special structure and large surface area make MOFs very attractive materials for next-generation, highly sensitive gas sensors. | |

| In new work, researchers at King Abdullah University of Science and Technology (KAUST) demonstrate a process that can be used for developing low-cost and highly sensitive gas sensors. By increasing the sensitivity, the amount of gas sensitive material and device size can be reduced which in turn would reduce the overall cost of the device and energy consumption. | |

| The team, led by Khaled N. Salama, an Associate Professor of Electrical Engineering andMohamed Eddaoudi, Distinguished Professor of Chemical Sciences and Director, Advanced Membranes and Porous Materials Research Center, both at KAUST, published their findings inSensors and Actuators B: Chemical ("The quest for highly sensitive QCM humidity sensors: the coating of CNT/MOF composite sensing films as case study"). | |

| "Conventionally, there are two types of nanocomposite materials used for fabricating gas sensors," Eddaoudi tells Nanowerk. "In the first approach, nanosized structures/particles are used as the skeletal material to enhance the surface area of the primary gas sensitive material. In the second approach, two or more gas sensitive materials are mixed/combined to form composites, which will enhance the overall device performance." | |

| Increased surface area is required for enhancing the performance of the materials used in sensing devices. MOFs are already know to have high surface area due to its porous structure (in a previous Nanowerk Spotlight we reported on the KAUST team's work with MOF-based gas sensors). However, the surface area can be further increased by reducing the crystal size of the MOFs. This can be done by forming composite with 1D porous materials. | |

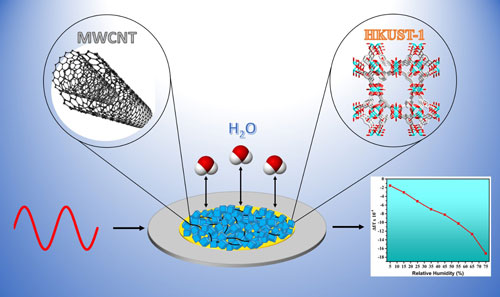

| "In our recent work" says Salama, "we combined the advantages of the two approaches, where both the materials used – HKUST-1 MOF and multi-walled carbon nanotubes (MWCNTs) – are individually nanostructured/porous (which possess/provide enhanced surface area) and are sensitive to a target analyte – water vapor in our case. Our main aim is develop low cost and highly sensitive gas sensors which are suitable for real life applications." | |

|

|

| Schematic of the QCM coated by HKUST-1 and CNT thin-film for Humidity sensing. (Image: Dr Karumbaiah N. Chappanda, KAUST) (click on image to enlarge) | |

| For their study, in addition to plain HKUST-1 and CNT thin films, the researchers prepared CNT-HKUST-1 composites of different weight ratios by dispersing different weight ratios of CNT with HKUST-1 base solution by ultra-sonication technique. The base mixtures were spin-coated onto a quartz-crystal microbalance (QCM) to fabricate electrodes. | |

| They then compared the performances of blank QCM, QCM coated with CNT, HKUST-1 and CNT-HKUST-1 composite thin films for detecting humidity. | |

| "HKUST-1 thin film with 0.5 mg CNT demonstrated the highest humidity sensitivity of -141 Hz per percent relative humidity, which is about 230% higher than that of plain HKUST-1 thin film," Dr Karumbaiah N. Chappanda, a postdoctoral fellow at the sensors lab and the lead author on the work, points out. "The Δf/f of our device is on par with or better than most previously demonstrated humidity sensors with low hysteresis and stable response, thereby making it a promising candidate for practical and highly sensitive humidity detection." | |

| The sensitivity-enhancement methodology presented in this work is simple and could be used to increase the sensitivity of other MOF-based gas sensors. | |

| The process developed can be used to improve the performance of the materials used for applications such as water splitting, solar energy harvesting and CO2 capture applications, which typically require materials with large surface area. | |

| Another interesting area to investigate is replacing MWCNTs with single-walled carbon nanotubes (SWCNTs) during synthesis of the composites. | |

| "Semiconducting SWCNTs have trans-conductive property, i.e. their conductivity can be tuned by gate voltage," notes Salama. "Using the gate voltage as an additional feature – for tuning the sensitivity – the composite's change in resistance can be used for sensing target analyte. The SWCNTs will function as resistive electrodes as well as skeletal materials for increasing the surface area of the material that is sensitive to a target analyte." | |

| "However, the key challenge is to find the right kind MOFs/CNT or/and MOF/MOF composites along with the right composition ratios," he concludes. | |

| By Michael Berger – Michael is author of two books by the Royal Society of Chemistry: Nano-Society: Pushing the Boundaries of Technology and Nanotechnology: The Future is Tiny. Copyright © Nanowerk |

Address: C508 Dingxin Building, Jilin University, 2699 Qianjin Street, Changchun 130012, P. R. China

Copyright © 2024 International Society of Bionic Engineering All Rights Reserved

吉ICP备11002416号-1

Copyright © 2024 International Society of Bionic Engineering All Rights Reserved

吉ICP备11002416号-1